Puck conveyor systems developed for battery production and its high requirements

Batteries and other energy storage devices play a crucial role in electromobility, as they significantly influence the reliability, performance and price of a system.

Manufacturers of lithium-ion batteries are therefore faced with a number of important requirements that have an impact on the high-performance and cost-effective, fully automated production of high-performance batteries. Some of these important requirements are:

Conveyor systems for the production of lithium-ion batteries by modular automation

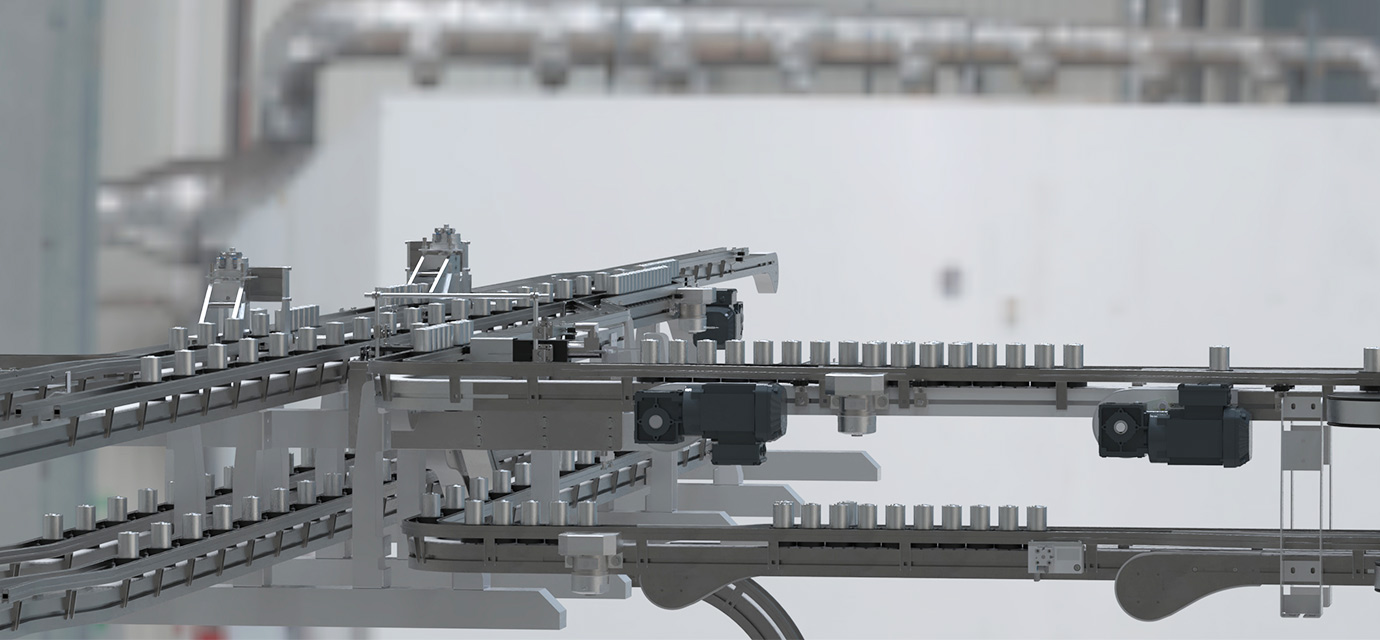

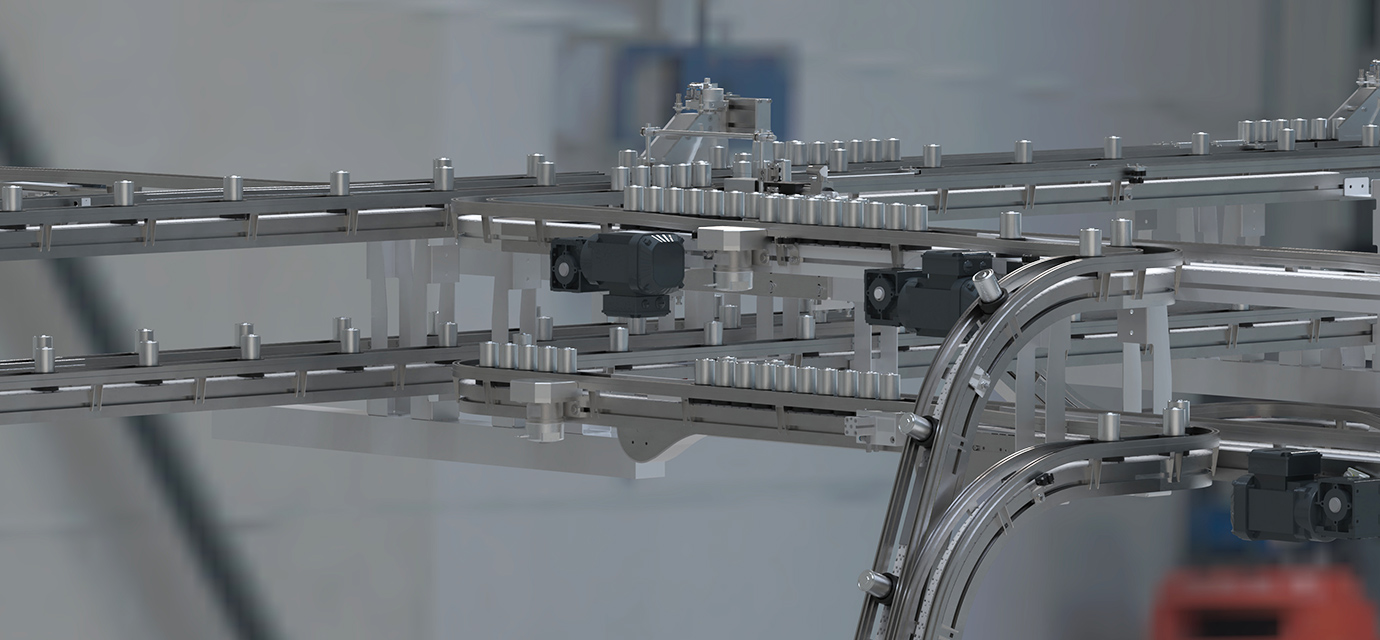

With our modular aluminium conveyor systems (plastic chain conveyors), we offer a wide range of high-performance interlinking solutions for battery production and the associated high requirements in terms of performance and output, environments (clean room, dry room) and efficiency and scalability in terms of line layout.

Our conveyor systems are space-saving and fit optimally into your production process. Our standardised modular conveyor system with different system sizes enables fast planning and delivery times at a good price. Our different system sizes allow us to react optimally to your product requirements.

Our conveyor technology solutions for battery production offer advantages for the following tasks:

- High performance transport and handling of battery cells

- Transport of battery cans and battery cases

- Transport of jelly rolls as part of the assembly process

- Transport of battery modules through the entire assembly process

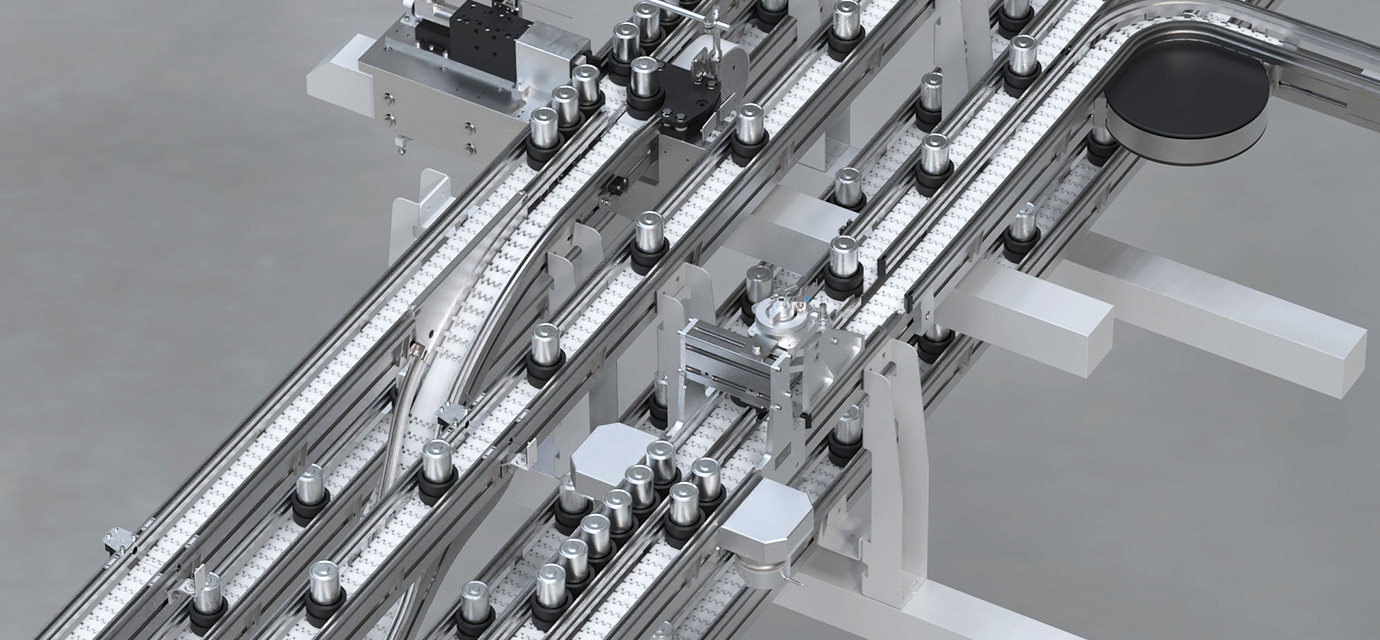

Puck conveyor systems for single-flow transport of battery cans and jelly rolls in lithium-ion battery production

Our puck conveyor systems convince with a very high output (outputs of over 450 PPM are possible), very high precision and process accuracy, as well as very flexible line layouts:

- Powerful vertical transport with pucks

- Very fast infeed and outfeed

- Flexible buffer sections in confined spaces

- High flexibility in puck distribution

This makes puck conveyor systems ideal for battery production, battery assembly and battery processing. The modular automation puck conveyor systems can be easily adapted to the customer's pucks (adaptations to side guides, switches for feeding and discharging, stoppers and separators, etc.). Alternatively, we are happy to develop a puck designed for the product and customer requirements. In doing so, we also draw on a modular puck design and years of experience. We use puck conveyor systems for the single-flow transport of battery cans and battery jelly rolls in the field of welding and winding processes. Here, the puck conveyor systems ensure the high demands on precision and reliability. Due to the flexible and compact line runs that are possible with puck conveyor systems, the pucks can be transported right into the welder and winder processes.

Our experience in the field of conveyor systems for battery production:

As an experienced supplier and manufacturer of automation solutions, we are proud to have been operating successfully as a system supplier in the battery supply and production market for many years. Thanks to our in-house modular conveyor system, we offer customised solutions for all needs - from large gigafactory systems to the supply of individual components. With years of know-how and a high capacity for innovation, we ensure that our customers from the battery manufacturing, electric battery production and e-mobility industries always benefit from our high level of experience in the planning and implementation of high-performance conveyor systems and palletising systems.

Our offering ranges from conveyor systems for battery cell production and battery module assembly systems to palletising and handling solutions. Discover the benefits of our wide range of conveyor system sizes and EuroPal palletising systems now.

Yourcontactforquestions&orders:

Do you have questions, would you like personal advice, in person on site, by phone, via MS Teams? We are happy to be at your disposal personally.