High flexibility in your production processes, thanks to buffers and increased autonomy

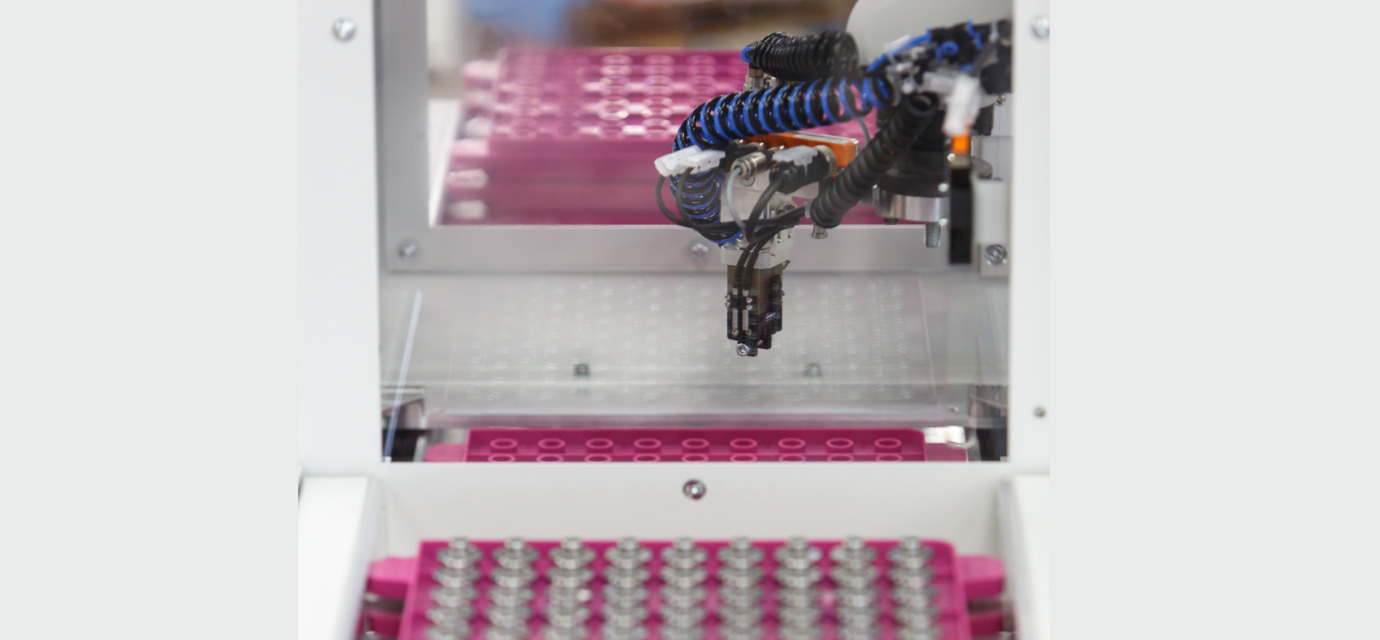

The EuroPal RTS tray stacking machine takes over the cost-effective supply or removal of workpieces with the aid of trays in automated production plants. It reduces manual work steps and in this way increases cost effectiveness in the production processes. Thanks to its compact construction, it is very space-saving and can be straightforwardly adapted to different machines. The integrated swivelling-arm robot offers additional flexibility and movement in the processes and has the advantage that a larger working radius is covered; it can also take over additional tasks in the automation process in the immediate vicinity of the EuroPal RTS, as it is outside the machine. The main task of the swivelling-arm robot is the unloading and loading of workpiece from or to the tray. During these tasks it operates very precisely and gently.

Thanks to comprehensive knowledge and know-how in the area of control and gripper technology, we can integrate the EuroPal RTS with integrated swivelling-arm robot optimally and seamlessly into your production steps. As a result your production steps become more effective and autonomous, consistently high production quality is ensured and costs are reduced due to the reduction in manual processes.