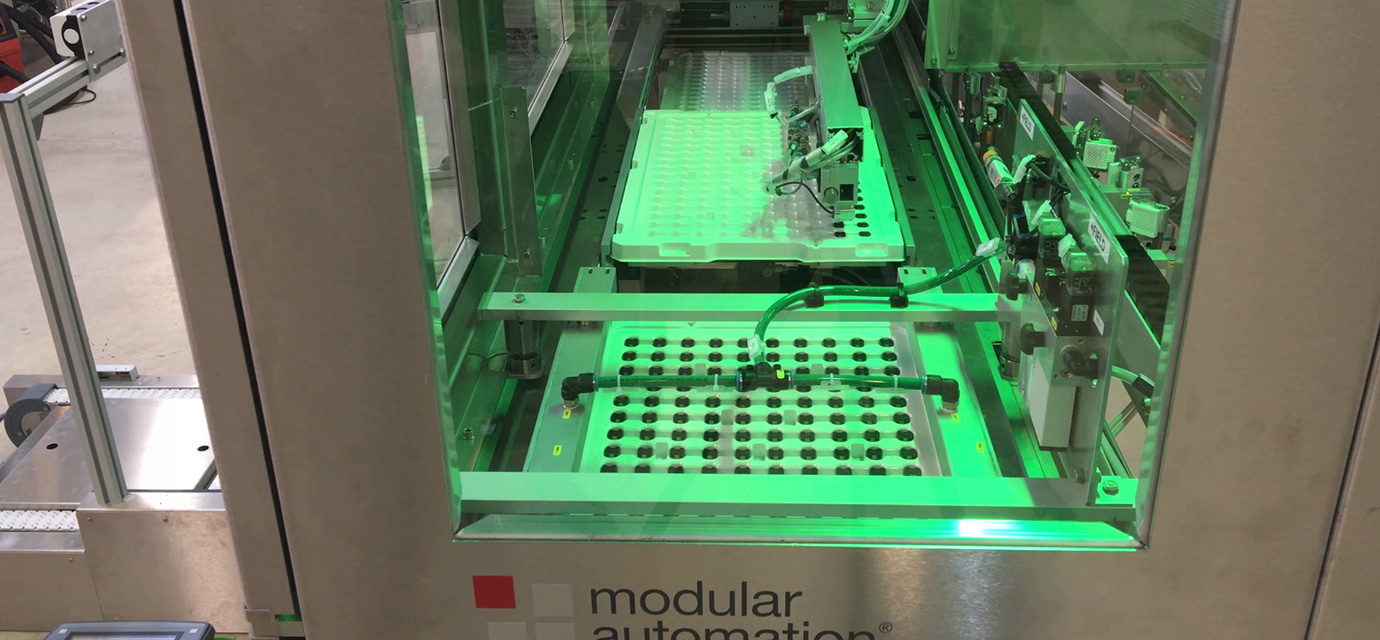

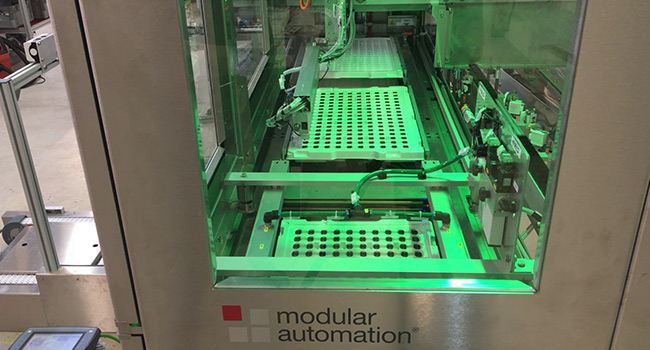

The high-speed EuroPal HP64 performance line speed (pls) palletising system with a tray change time of less than 2 seconds

With increasing requirements in terms of performance and output in assembly systems and assembly processes, the demands on parts feeding, parts removal and parts buffering and thus on the performance of palletising systems, or tray changing systems, are also increasing.

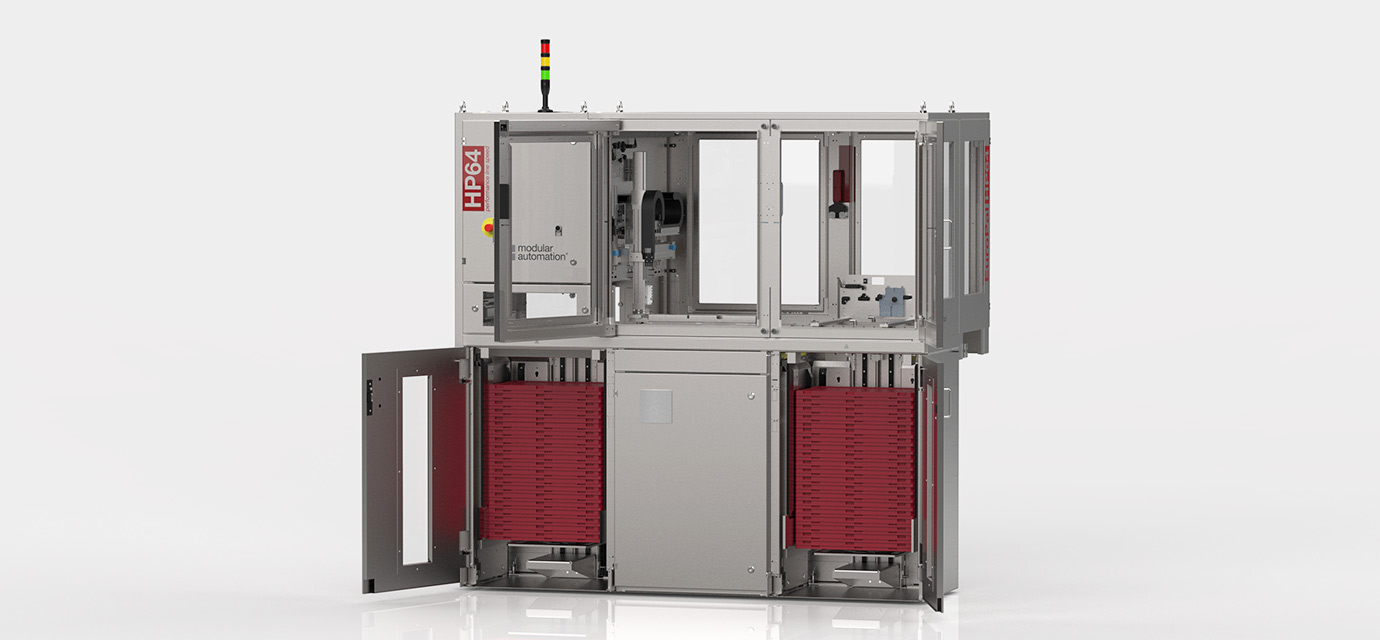

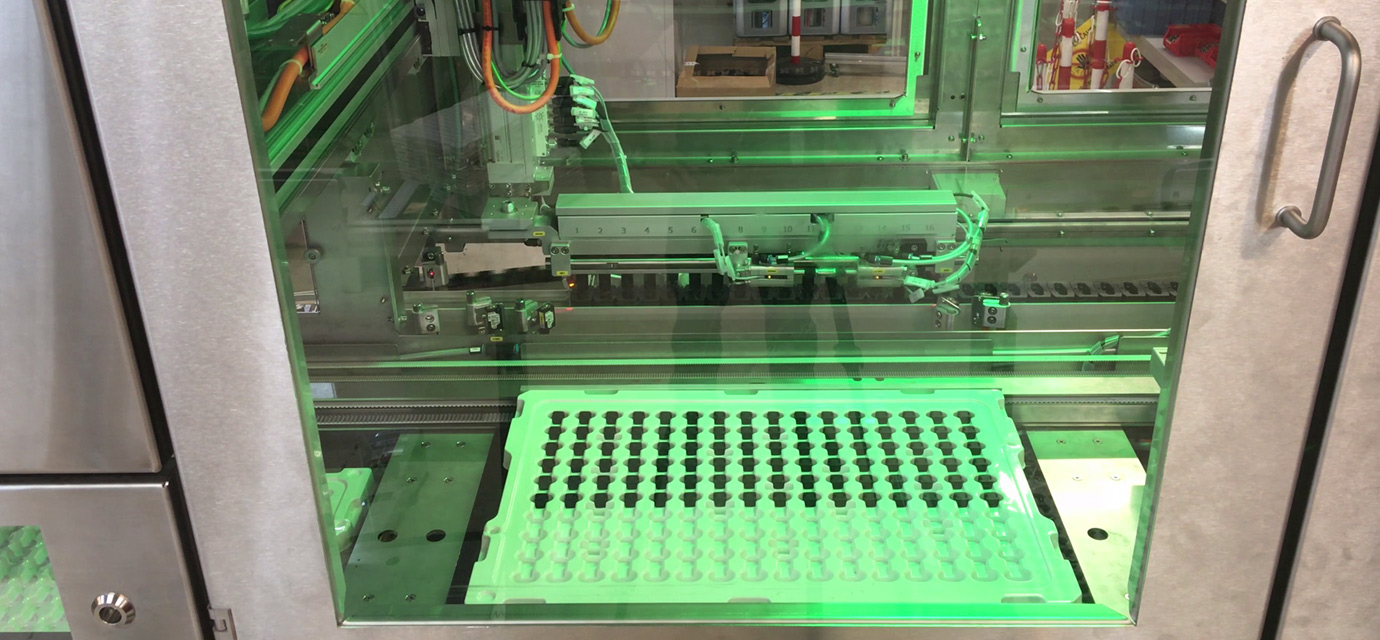

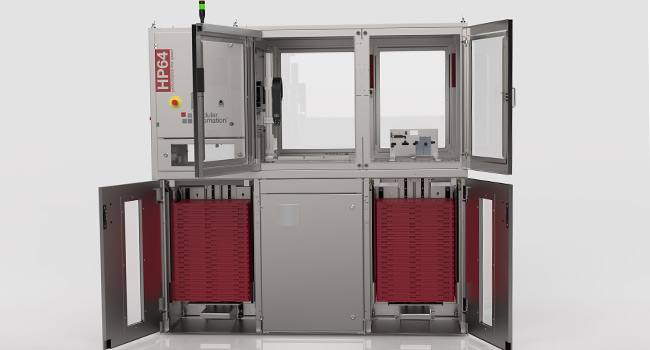

We have taken on these increased requirements and developed the new EuroPal HP64 perfomance line speed (pls) high-speed palletising system, which operates with a tray changeover time of less than 2 seconds. The EuroPal HP64 pls is a palletising system with integrated handling and is designed for trays/pallets with dimensions of up to 600 x 400 mm (L x W). It also impresses with its very compact and space-saving design (footprint), as a linear axis system is integrated in the palletiser and therefore no additional space is required. this means that the palletising system can be integrated quickly and easily into your production environment as an interface. The machine is designed in such a way that it does not have to be disassembled for transport. This enables a quick commissioning or an uncomplicated relocation within your production hall.

The EuroPal HP64 pls palletising system is also available without an integrated linear axis system. Please do not hesitate to contact us directly.