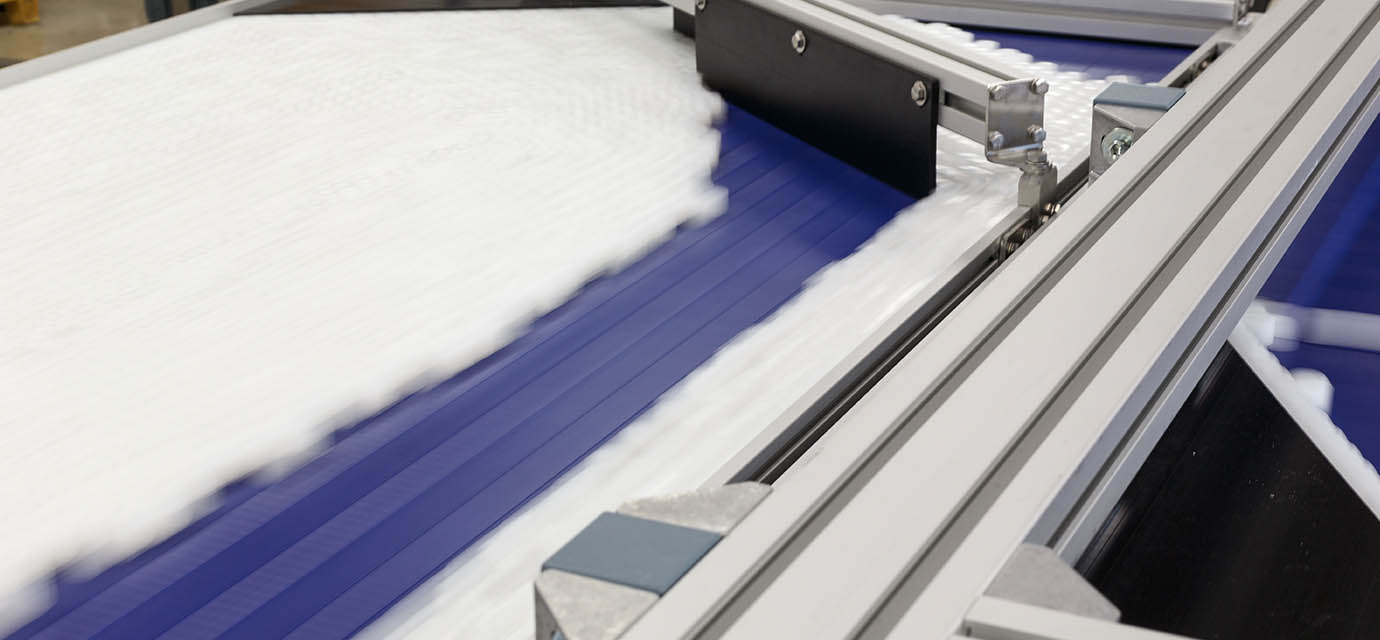

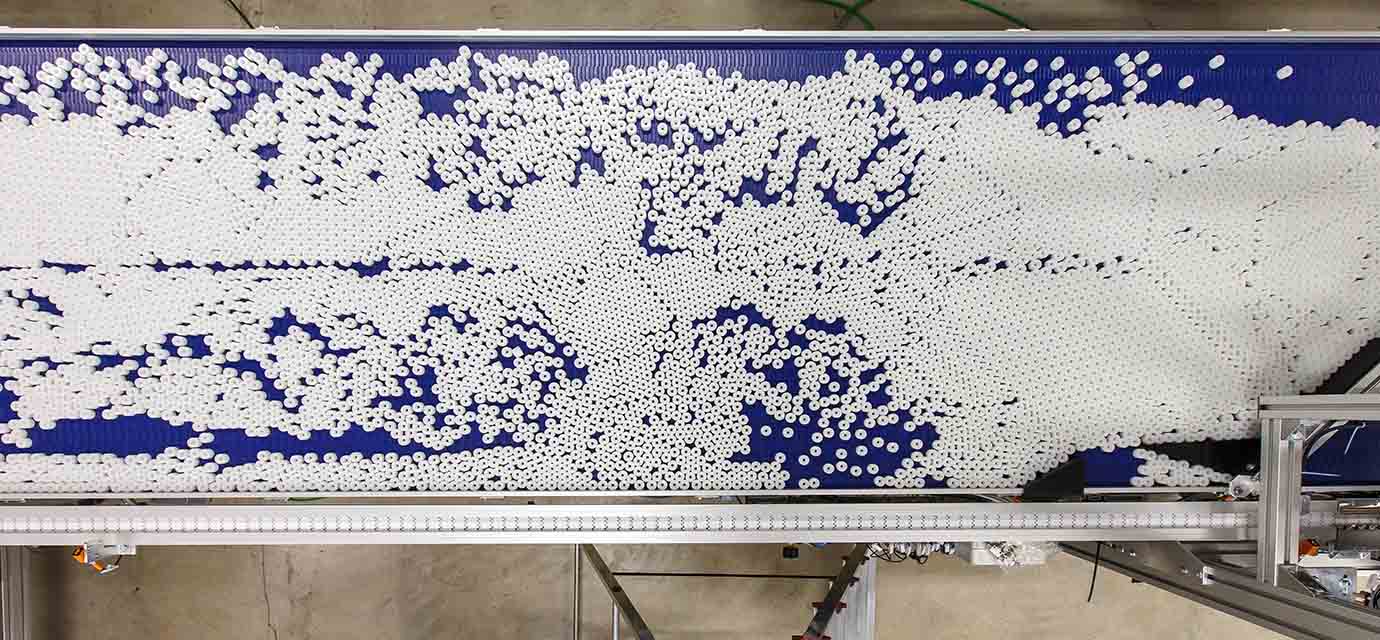

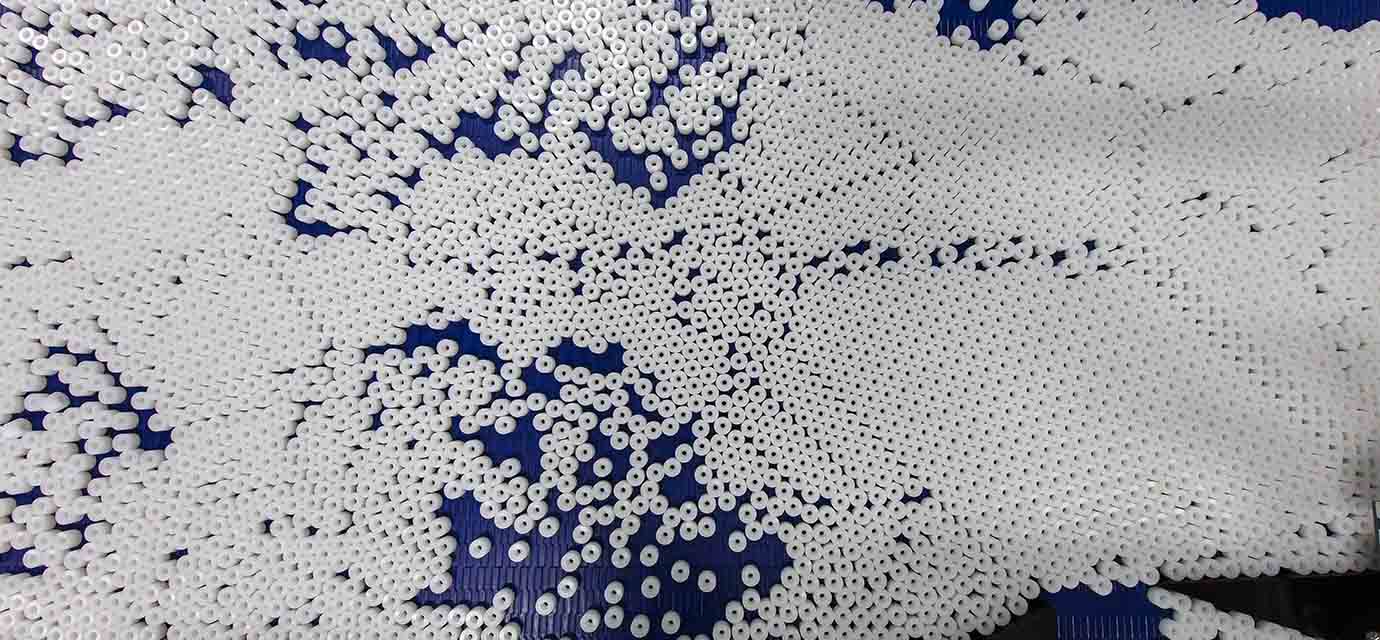

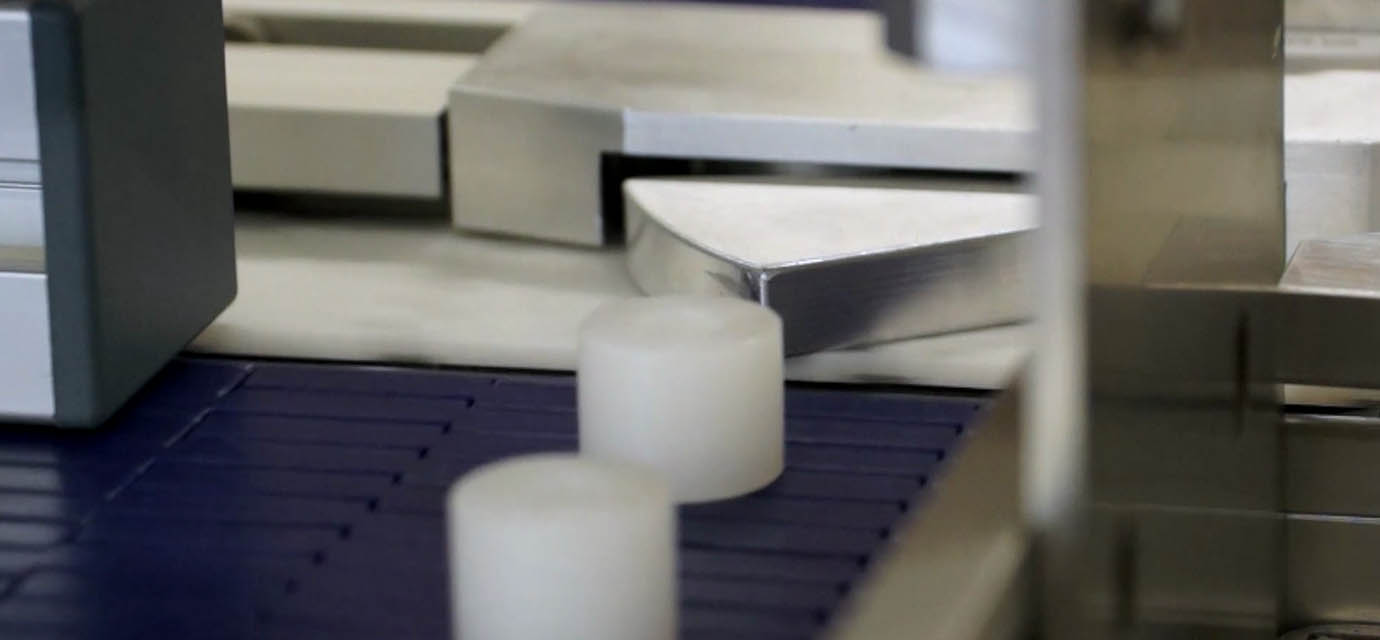

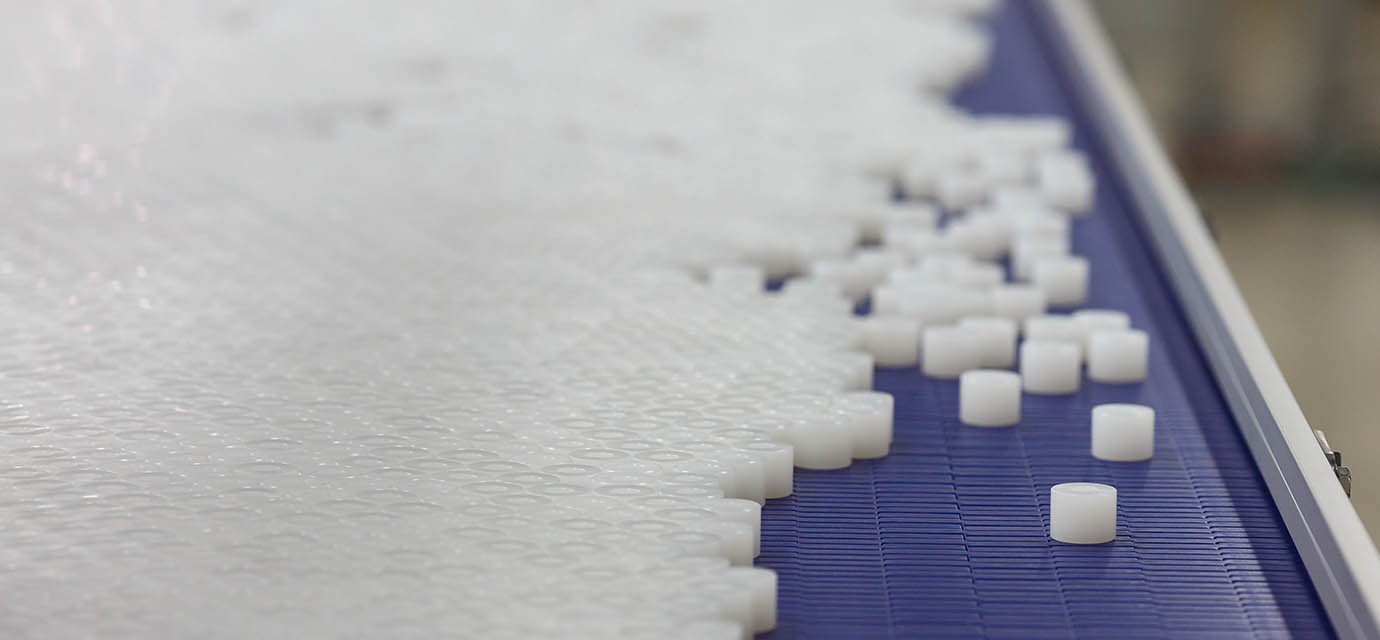

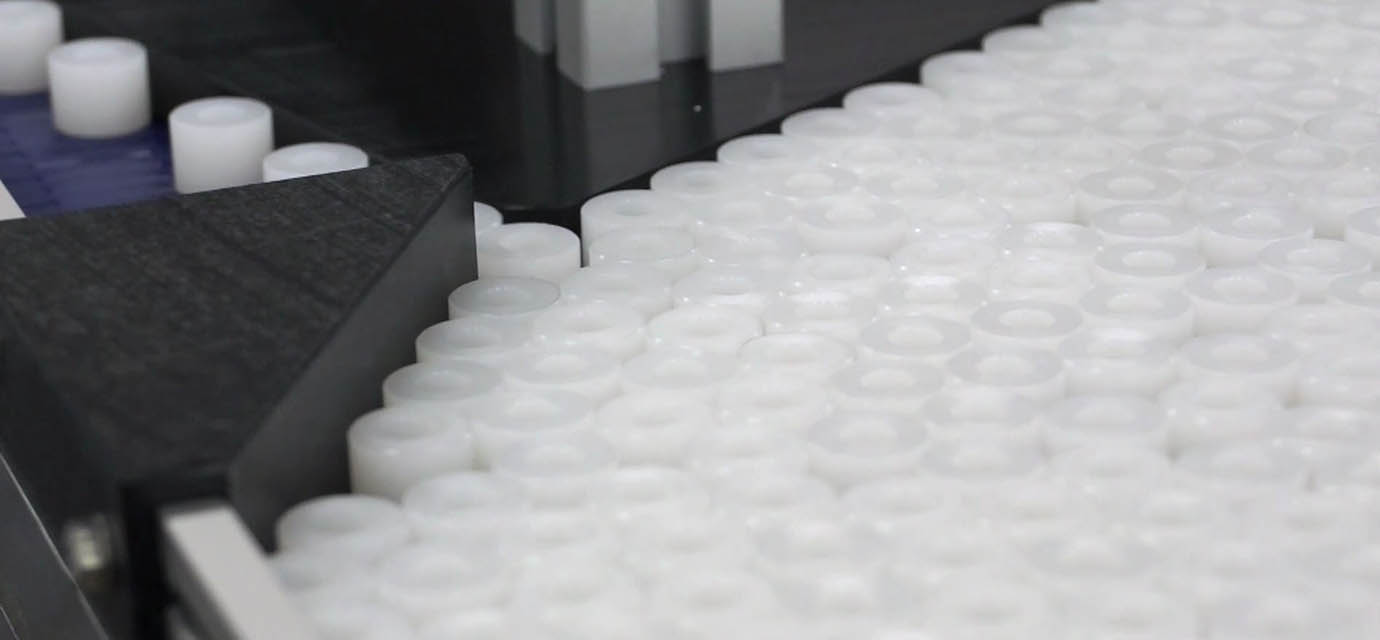

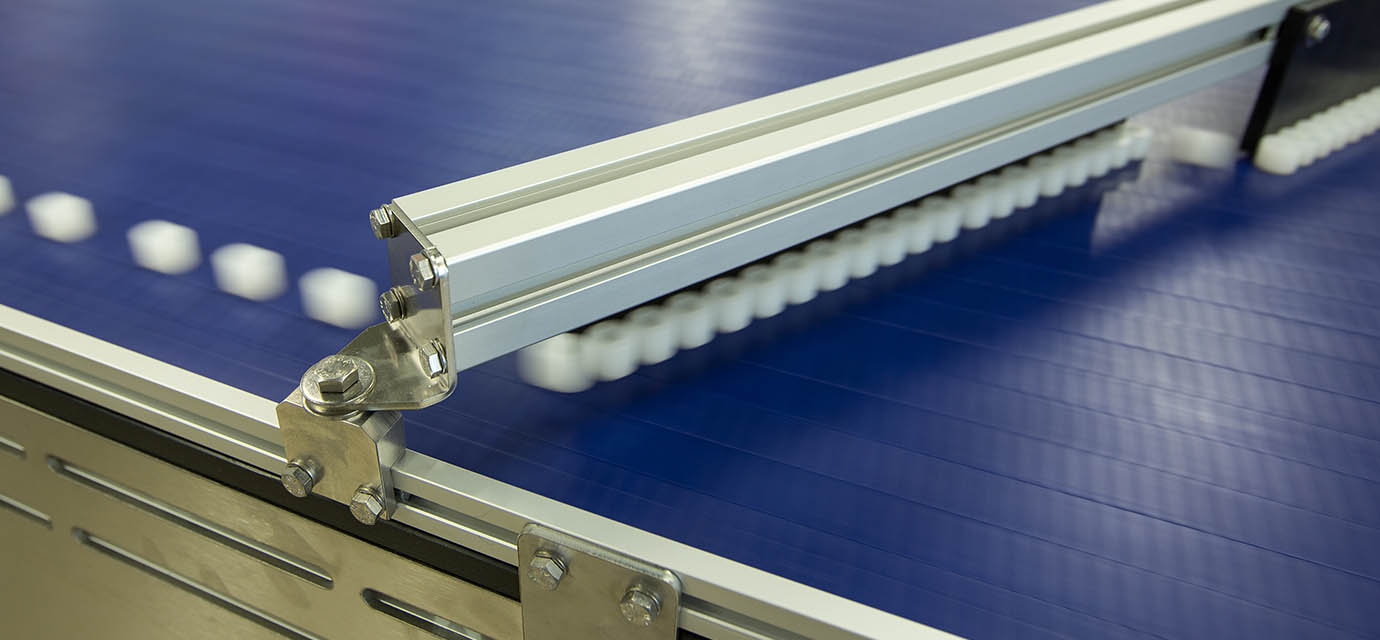

Area storage systems: Storage tables / buffer tables increase production capacity and create valuable buffers in conveyor lines and conveyors.

Buffer tables belong to the area storage systems and are also known as storage tables, accumulation tables, area buffers or buffer conveyor belts. They belong to the area buffers and are an alternative to the distance buffers (conveyors/screw conveyors). These conveyor technology storage systems are used in conveying processes and plants to optimize processes and make them more fail-safe by ensuring a continuous flow of material even during short interruptions and, for example, by bridging and intercepting machine breakdowns or downtimes.