Areas of application for alpine conveyors / accumulating conveyors - Tasks of a spiral storage system in the production process

A alpine conveyor can be used in a wide variety of applications, such as stowing products, connecting machines with different speeds, bridging height differences or using specific functions such as cooling products. The different areas of application are described below:

1. Conveyor with accumulation function - alpine conveyor as buffer/storage zone or buffer for transported goods

Buffers are required in the production process for various reasons. If machines fail for a short time due to machine failures, maintenance or repairs, accumulating conveyors or spiral conveyors can compensate for the failure for a short period of time by either feeding the next machine or by collecting the failure of the following machine, in which they pick up and store the processed material until it is ready for use again.

2. Accumulating conveyors: connecting production lines with different cycles (speeds)

The buffer zone of the alpine conveyor is also used to connect production lines operating at different speeds. The accumulating conveyor serves here as a buffer for transported goods. By means of suitable process control, it is also possible for machines to be buffered at different speeds by the alpine conveyor.

3. Accumulation conveyor section with additional function: alpine conveyor as drying section or cooling section

In some production processes it is necessary that the transported goods have to be dried or cooled in the production process. The accumulating / alpine conveyor with its long transport distance is ideally suited for this purpose, which is very space-saving due to its serpentine arrangement.

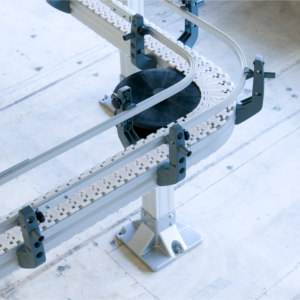

4. Alpine conveyor / spiral accumulator for bridging height differences in the production process

A further function of the alpine conveyor (storage conveyor) is that it can bridge height differences and at the same time create buffers in the production process. The alpine conveyor is a very space-saving solution if, for example, transport goods have to be transported up or down for processing or if passageways or forklift routes have to be kept clear.