Uhlmann and modular automation: Jointly developed pharmaceutical final packaging line for medical products sets new standards.

For a well-known pharmaceutical group, modular automation, together with Uhlmann Pac-Systeme GmbH & Co. KG, developed an ultra-modern and innovative production plant, which is characterized by high performance and flexibility. In addition to a puck (product carrier) conveyor system, the plant consists of a depalletizing, labelling and cartoning process.

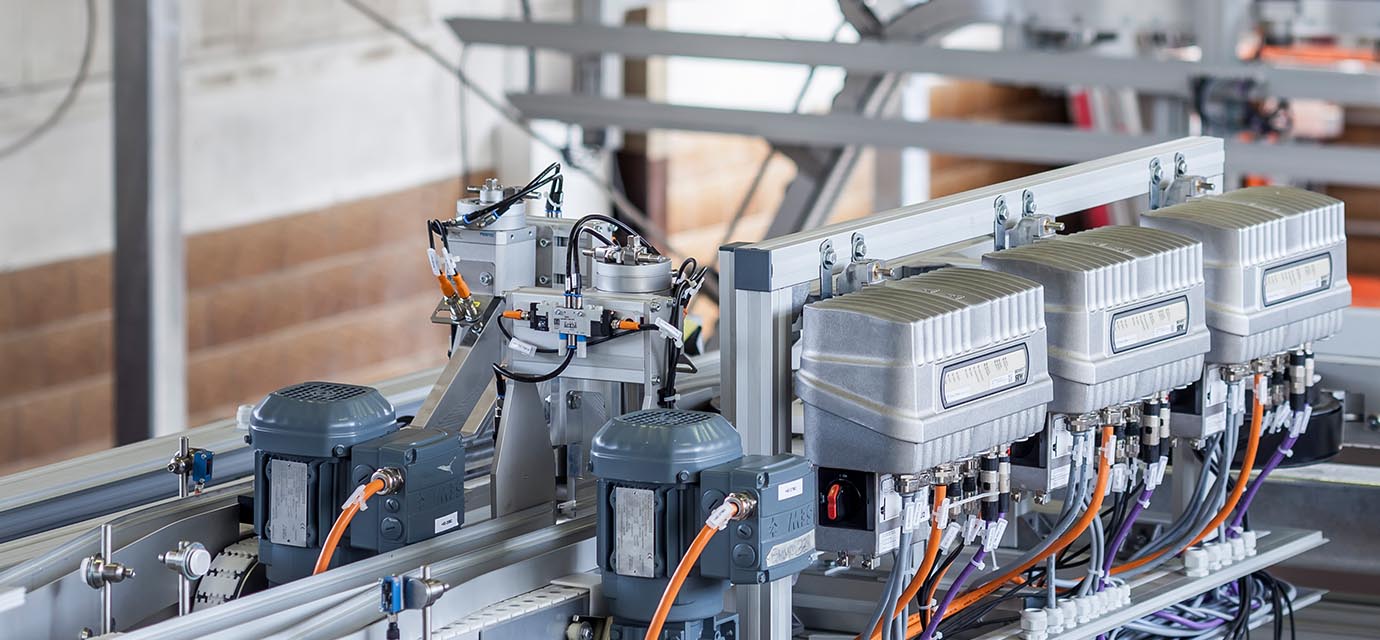

The Puck transport system developed by modular automation, also known as the Puck Handling System, combines the three system processes provided by Uhlmann and ensures optimum plant utilization through efficient puck handling and an optimized material flow (one-piece flow solution).

Challenges for the chain conveyor system: flexibility, space saving, energy savings

The challenges posed to the conveyor system or chain conveyor with puck handling were to develop a space-saving conveyor system that allows a high degree of flexibility, in which it can react quickly and easily to real-time conditions in the production process. In addition to high performance (200 products per minute), the plant should also be able to compensate for short-term machine downtimes and compensate for production fluctuations between the individual process steps.

The system developed by modular automation consists of a total of three buffers (buffer sections), two Alpine buffers and the conveyor section as the third buffer, each of which has been placed between the various system processes (depalletizing, labelling and cartoning processes). Thanks to the buffers, it is possible to compensate briefly for machine downtimes or performance fluctuations of the individual processes. Each buffer has a capacity of 750 pucks.

For space reasons, almost the entire conveyor system (link chain conveyor with puck handling) was installed on a three-metre high steel frame in order to be able to use the entire floor area for the processes (depalletizing, labelling and cartoning process).

A powerful controller registers all process requirements in real time, monitors and controls all material flows to ensure an optimal supply of the processes. Frequency-controlled drives adapt the feed rate (speed) of the system in real time to the production requirements. Non-required plant components, e. g. buffers, are automatically identified and switched off by the control system and only switched on again when required. This saves energy and also significantly reduces the noise level.

Pucks & Puck-Handling: Product carrier made of plastic developed in 3D printing process

The pucks (product carriers / workpiece carriers) developed by modular automation in the 3D printing prototyping process provide a further great energy saving potential. As part of the development process and through extensive testing on test facilities, we have succeeded in reducing the empty weight of the pucks by about two thirds compared to conventional pucks. As a result, the energy consumption of the puck-handling-conveyor system could be reduced by approx. 25%. Damping buffers are injected into the pucks in a 2-component process (multi-component injection moulding), which significantly reduces the noise level of the system during operation.

Side rails developed for puck transport

Especially for this project and the task modular automation developed and manufactured a special side rail, which guides the pucks safely through the plant. A steel sheet was incorporated into the pucks so that the pucks can be easily transported vertically with the aid of a magnetic chain, even on steep plant sections. Thanks to the side rail and the magnetic chain, it is also possible to run overhead (360 degree loops).

Modular system design reduces assembly and disassembly costs

Another special feature of the system is its modular design, which has already been given special attention during planning and construction. Integrated plant sections were divided into transportable functional units. This makes it possible to dismantle the system within only four working days and to completely reassemble it within eight working days. This saved our customers unnecessary costs and important time.