Chain conveyor slide strips for beams

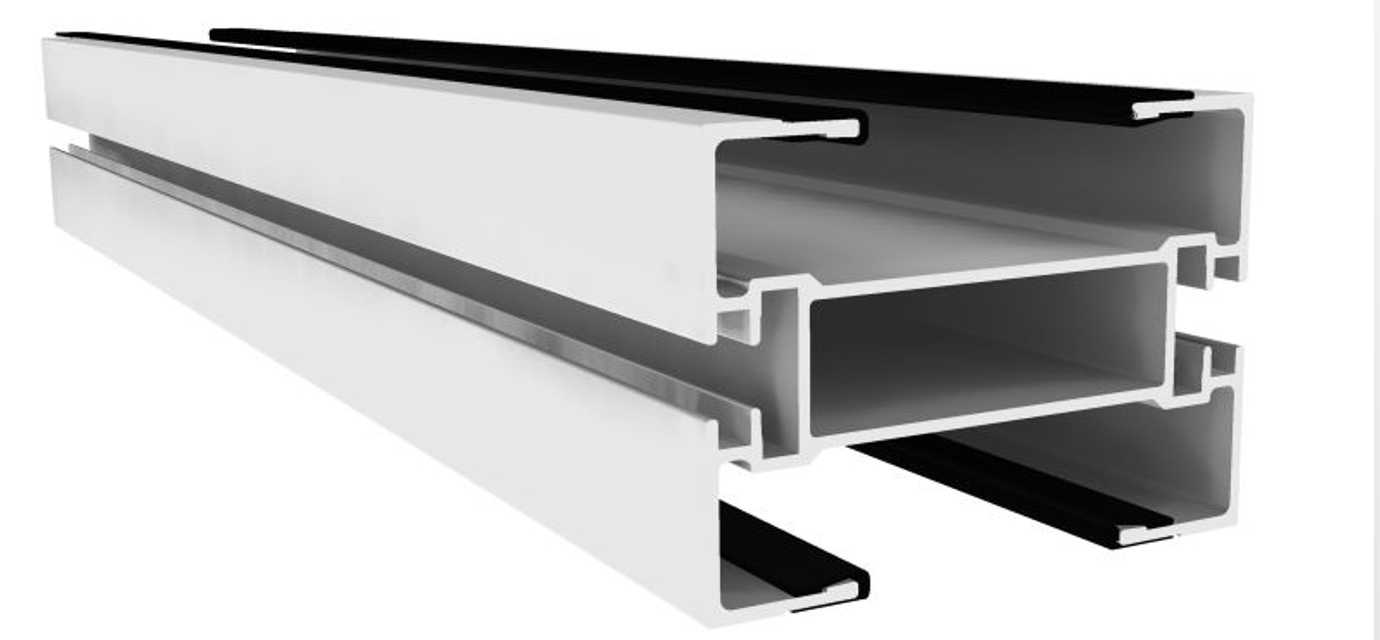

The beams are made of aluminium, the plastic chain that can move around bends runs along them. Between the beam and plastic chain there is the slide strip, also called the slide rail. On the following pages you will find an overview of all beams and all chain types from modular automation.

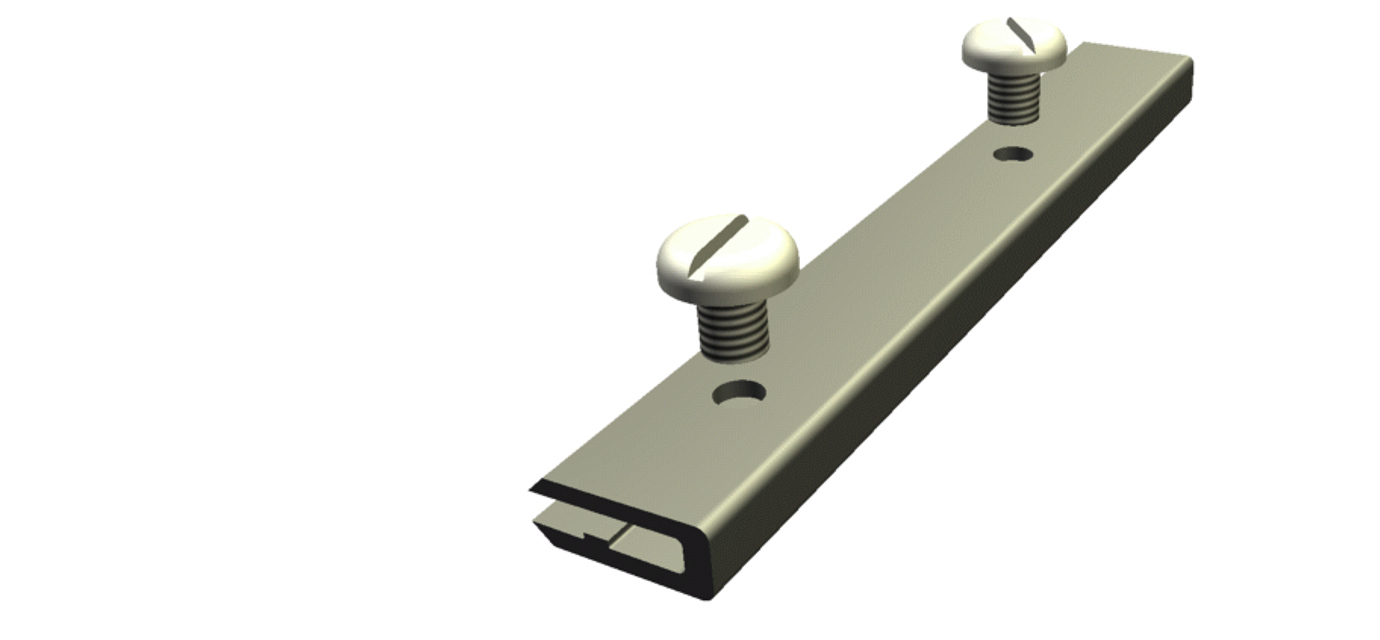

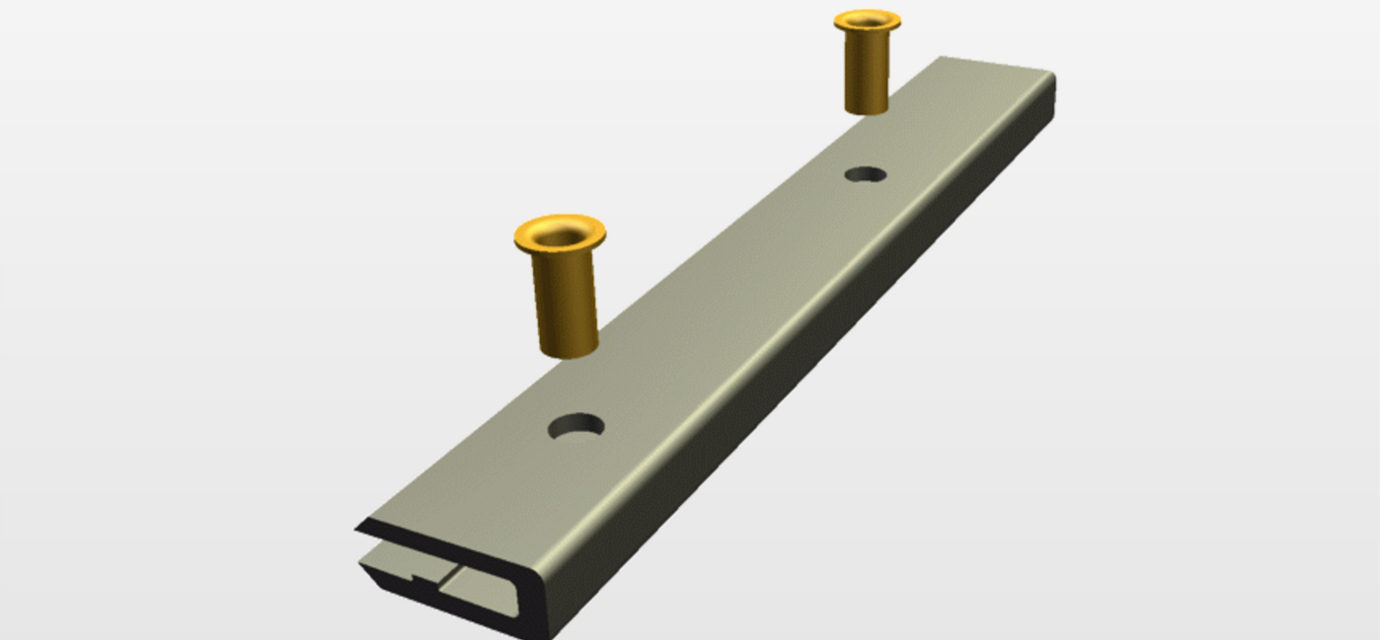

Slide strips or slide rails made of plastic or spring steel strip are used to reduce the friction between the beam and the chain and are fastened to the beam using rivets, adhesive or screws. The slide strip is installed with the greatest possible care to ensure the conveyor chain runs smoothly. The slide strips are available in five different material designs.