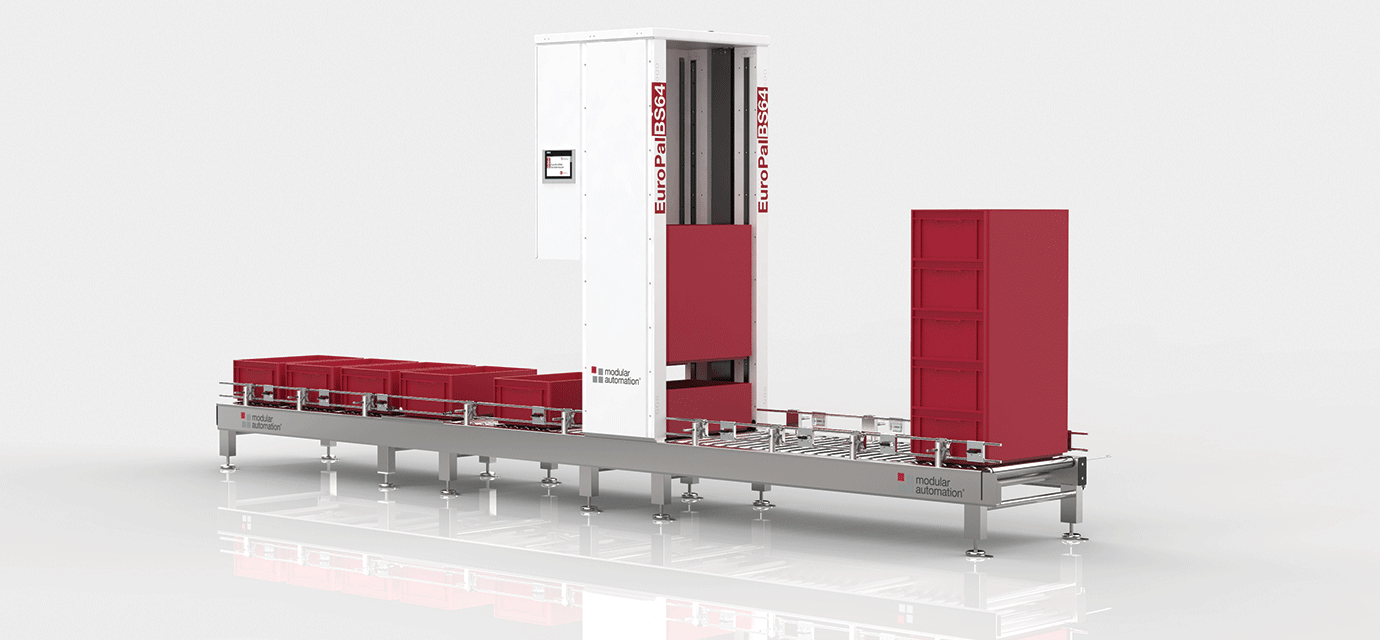

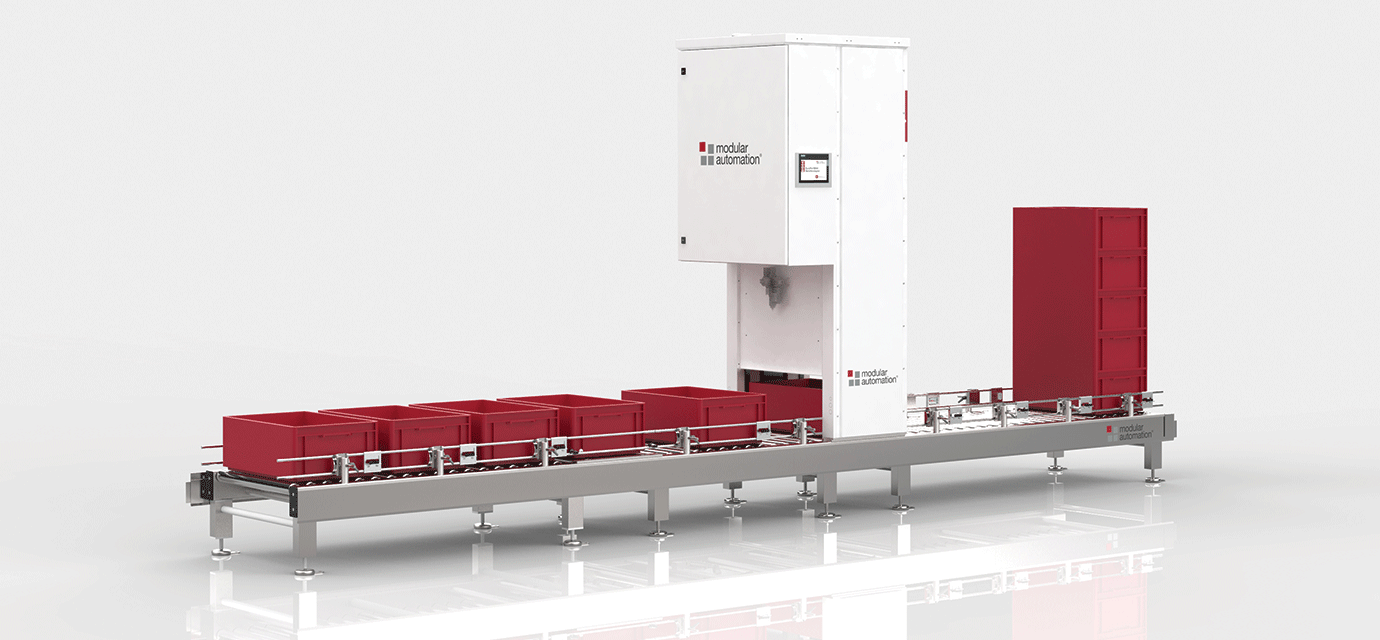

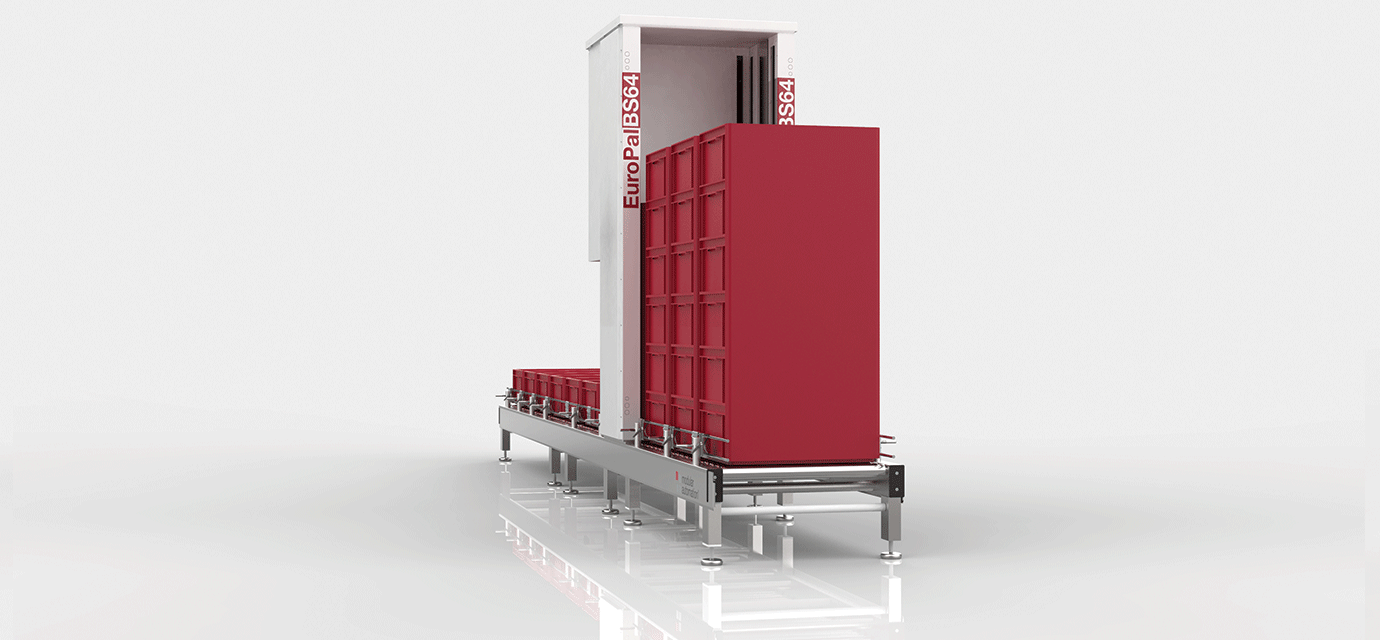

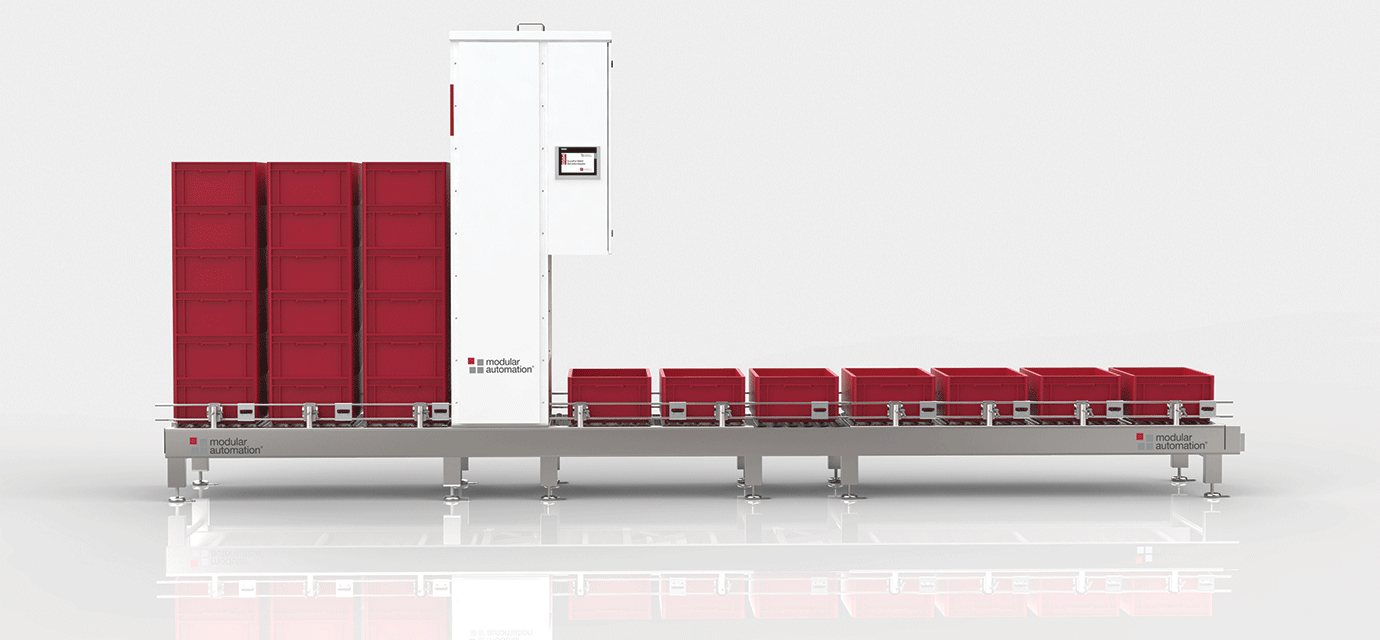

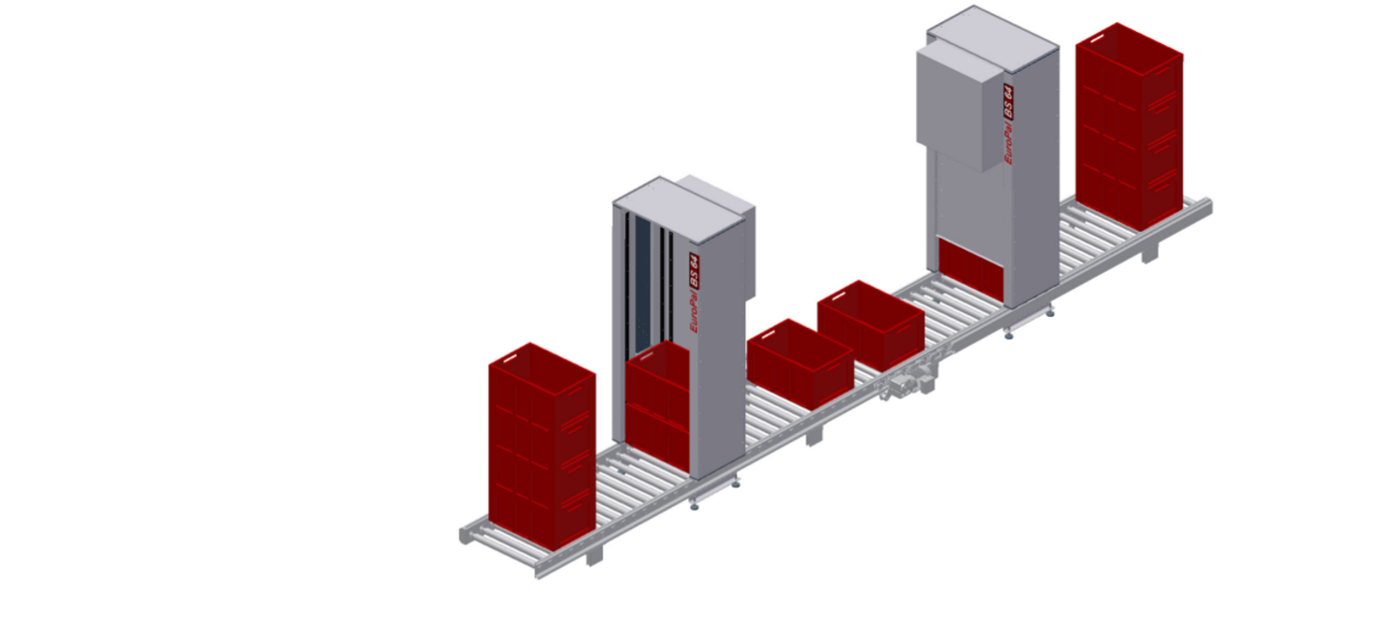

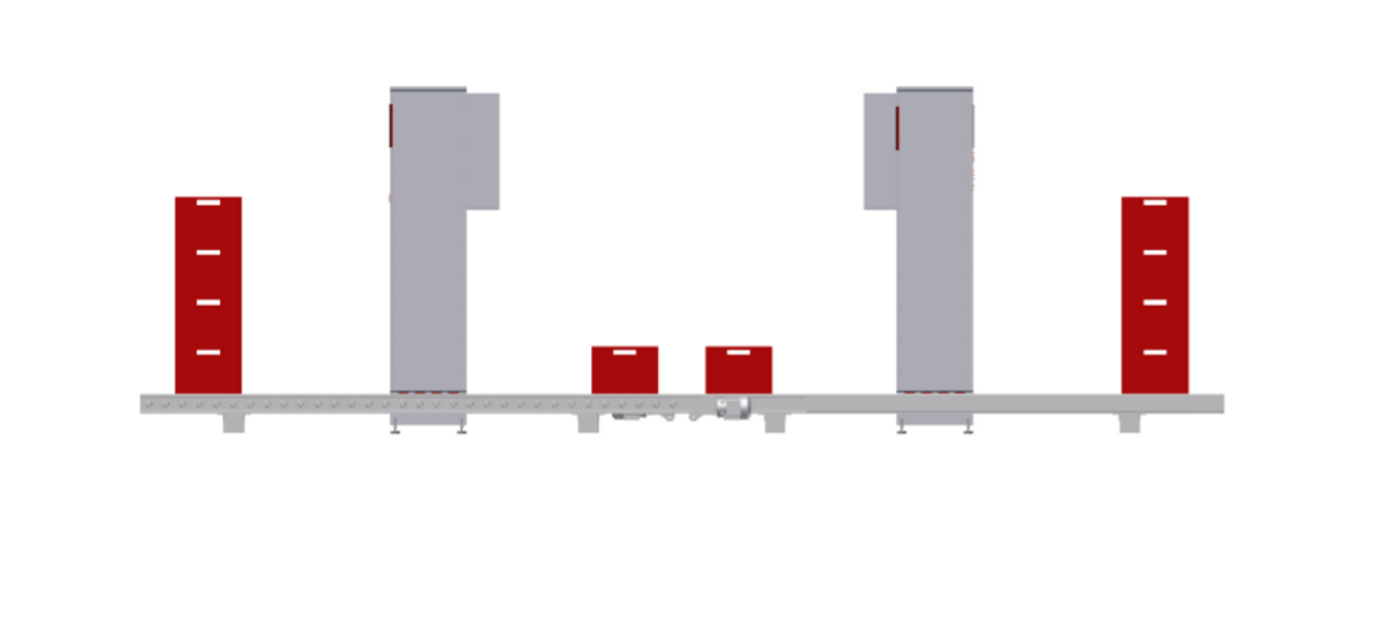

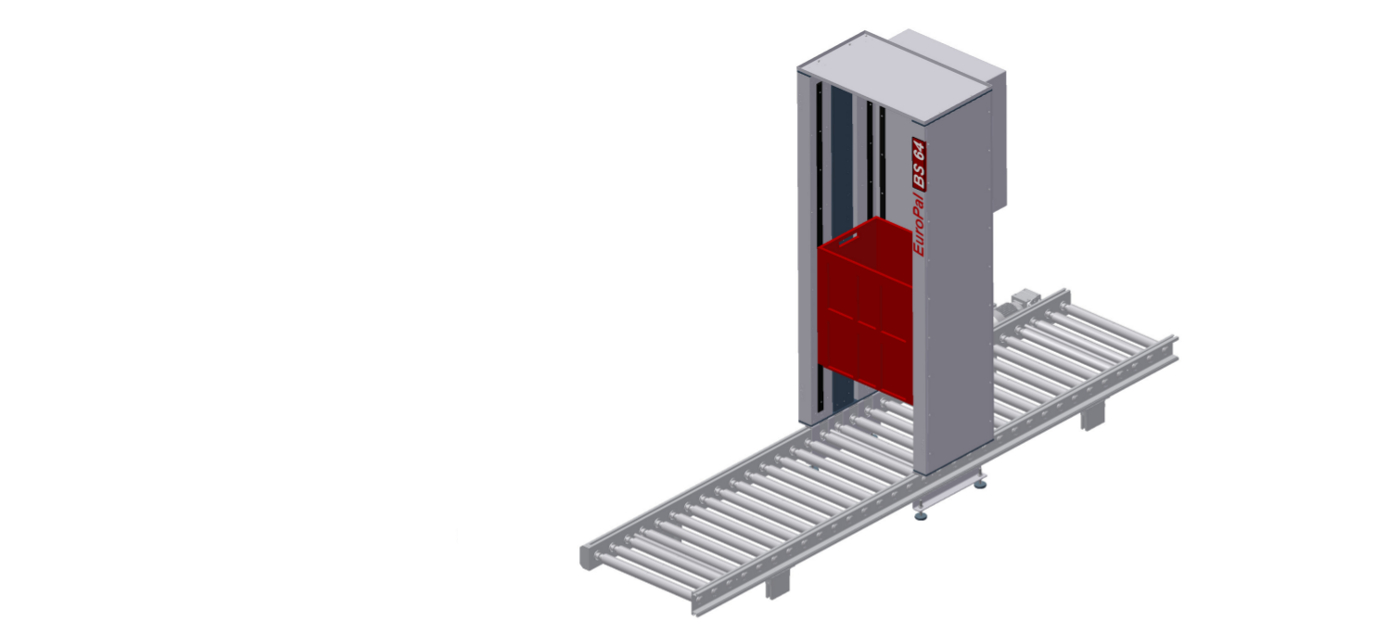

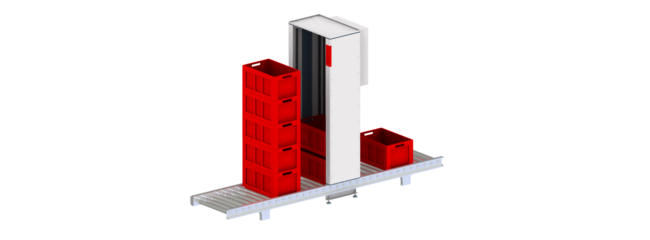

The container stackers EuroPal BS – space-savingly stack and unstack containers, boxes and standard containers

The container stacking and unstacking system EuroPal BS effortlessly stacks standard containers and receptacles even with higher loads. The most space-saving container stacker on the market stacks and unstacks containers, boxes and standard containers, for this reason it is suitable for your factory and production logistics as an efficient tool. Particularly if there are a large number of containers, the EuroPal BS ensures space-saving storage of empty and full containers / boxes and, if necessary, automatically passes these containers / boxes on to the system or the production process.

Using the container / boxes stacker you can create a buffer of empty and full containers / boxes in your production processes, as a consequence there is a significant storage and space-saving potential in a very small space. Due to the modular construction, the EuroPal BS container stacker can be adapted to every type of container. Subsequent adaptation to other container types is also possible without problems.